Odorous gas online monitor XDB-EC01

First, odor gas online monitor introduction:

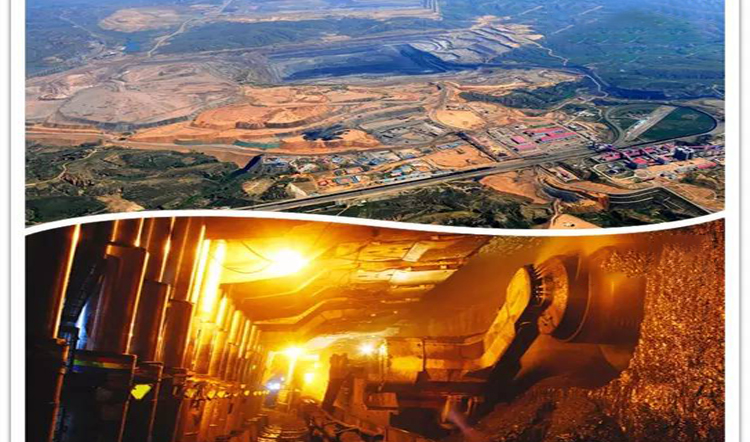

The online odor gas monitor XDB-EC01 is a common equipment for detecting odor gas emitted in large-scale industrial areas and infrastructure. Such as chemical plants, perfume factories, coating factories, food fermentation plants, pesticide plants, livestock plants, etc., which is characterized by a large amount of odor production, some odor or toxic gases, there is a greater harm to human health. The instrument monitors the ambient air in real time through the built-in multi-principle imported odor detection sensor, and uses the model presented by the data measured by the meteorological detection equipment (temperature, humidity, wind direction, wind speed, atmospheric pressure) to predict the direction and diffusion of gas pollutants or odors to understand its impact on the surrounding area. The sensor technology is organically combined with pattern recognition technology and computer technology, which can quickly and accurately identify the concentration of various gases in the complex environment of several mixed gases, and realize quantitative analysis and timely alarm.

2. Introduction of supporting data software:

Online air quality automatic monitoring system software, it is through the use of wireless GPRS data transmission with 120 monitoring sub-stations, the monitoring data real-time transmission to the local environmental monitoring center; The center can monitor the real-time dynamic data of the online monitoring equipment distributed in the area through the system real-time monitoring terminal, and record it in time; Establish a monitoring system database, predict and forecast the environmental pollution status and development trend in the area according to the historical record data and analysis results, and provide a scientific basis for effectively controlling the environmental status in the area.

Third, odor gas emission standards:

Control item unit Level 1, Level 2, Level 3 Remarks

New and existing. New and existing

1 Ammonia mg/m3 1.0 1.5 2.0 4.0 5.0

2 Trimethylamine mg/m3 0.05 0.08 0.15 0.45 0.80

3 Hydrogen sulfide mg/m3 0.03 0.06 0.10 0.32 0.60

4 Methylmercaptan mg/m3 0.004 0.007 0.010 0.020 0.035

5 Methyl sulfide mg/m3 0.03 0.07 0.15 0.55 1.10

6 Dimethyl disulfide mg/m3 0.03 0.06 0.13 0.42 0.71

7 Carbon disulfide mg/m3 2.0 3.0 5.0 8.0 10

8 Styrene mg/m3 3.0 5.0 7.0 14 19

9 Odor concentration has no dimension 10 20 30 60 70

Fourth, odor gas hazards:

1. Mild poisoning

Mild intoxication is mainly irritating symptoms, manifested as tears, stinging eyes, runny nose, burning sensation in the throat, or accompanied by headache, dizziness, fatigue, nausea and other symptoms. The examination showed congestive eye conjunctiva and rales in the lungs, which could be recovered within a short time after discontact.

2. Moderate poisoning

After exposure to high concentration hydrogen sulfide, the symptoms of encephalopathy were significant, including headache, dizziness, agitation, staggering gait, irritability, confusion, delirium, seizure-like convulsions may be generalized tonic-clonic seizures. A sudden coma may occur; Dyspnea or cardiac arrest after respiratory arrest may also occur. Fundus examination showed that there was papilledema of optic nerve in individual cases. Some cases may be accompanied by pulmonary edema. Symptoms of encephalopathy often appear earlier than respiratory symptoms. Chest X-ray shows enhanced lung texture or patchy shadows.

3. Severe poisoning

Electrocution-like death can occur after exposure to extremely high concentrations of hydrogen sulfide, that is, respiratory arrest within seconds or minutes after exposure, and cardiac arrest can occur after a few minutes. They may also pass out immediately or within a few minutes and die from respiratory arrest. Death can occur without alertness, with immediate anosmia when the smell of hydrogen sulfide is detected, and in a few cases, a sickening sweet smell can be detected immediately before coma. There are generally no premonitory symptoms before death, and breathing may first appear deep and fast, followed by respiratory arrest.

5. Monitoring parameters:

Name range resolution

Stench 0-1000OU 1

Ammonia 0-5mg/m³ 0.1mg /m³

Hydrogen sulfide 0-200ug g/m³ 0.01 mg/m³

Trimethylamine 0-100ug g/m³ 0.01 mg/m³

Methyl mercaptan 0-100ug g/m³ 0.001 mg/m³

Methyl sulfide 0-100ug g/m³ 0.01 mg/m³

Dimethyl disulfide 0-100ug g/m³ 0.01 mg/m³

Carbon disulfide 0-100ug g/m³ 0.1mg /m³

Styrene 0-100ug g/m³ 0.1mg /m³

VOCs 0-50ug g/m³ 0.001 mg/m³

Six, equipment technical parameters:

Sampling temperature -20℃ ~ 50℃

Operating temperature -20℃ ~ 50℃

Operating humidity 0-95%RH

Power supply <AC220V 50HZ (built-in leakage and surge protection), optional solar panel (DC21V100W)

Internal power supply equipped with 12V10AH, lead-acid battery, can work for 48 hours without power

The data is stored for more than five years

Box material steel

The air chamber design adopts polytetrafluoroidal material integrated design

Response time odor Analysis ≤ 5s, gas < 10 seconds

The measurement error of odor concentration and three-point comparison odor bag method (GBT 14675-1993) is less than 15%. Other factors ± 5%FS

Automatic zero calibration supports automatic zero calibration function, and the period of automatic zero calibration can be set and modified by the user

Hydrogen sulfide and ammonia need to be calibrated by standard gas. The national standard detection method for odor concentration OU value is GB14675 three-point comparative sniffing bag method, and the monitoring results should support conic curve fitting according to the national standard detection results

Sample retention system is equipped with online automatic sample retention system

Communication protocol Wireless or wired (built-in HJ212 protocol)

简体中文

简体中文 ENGLISH

ENGLISH