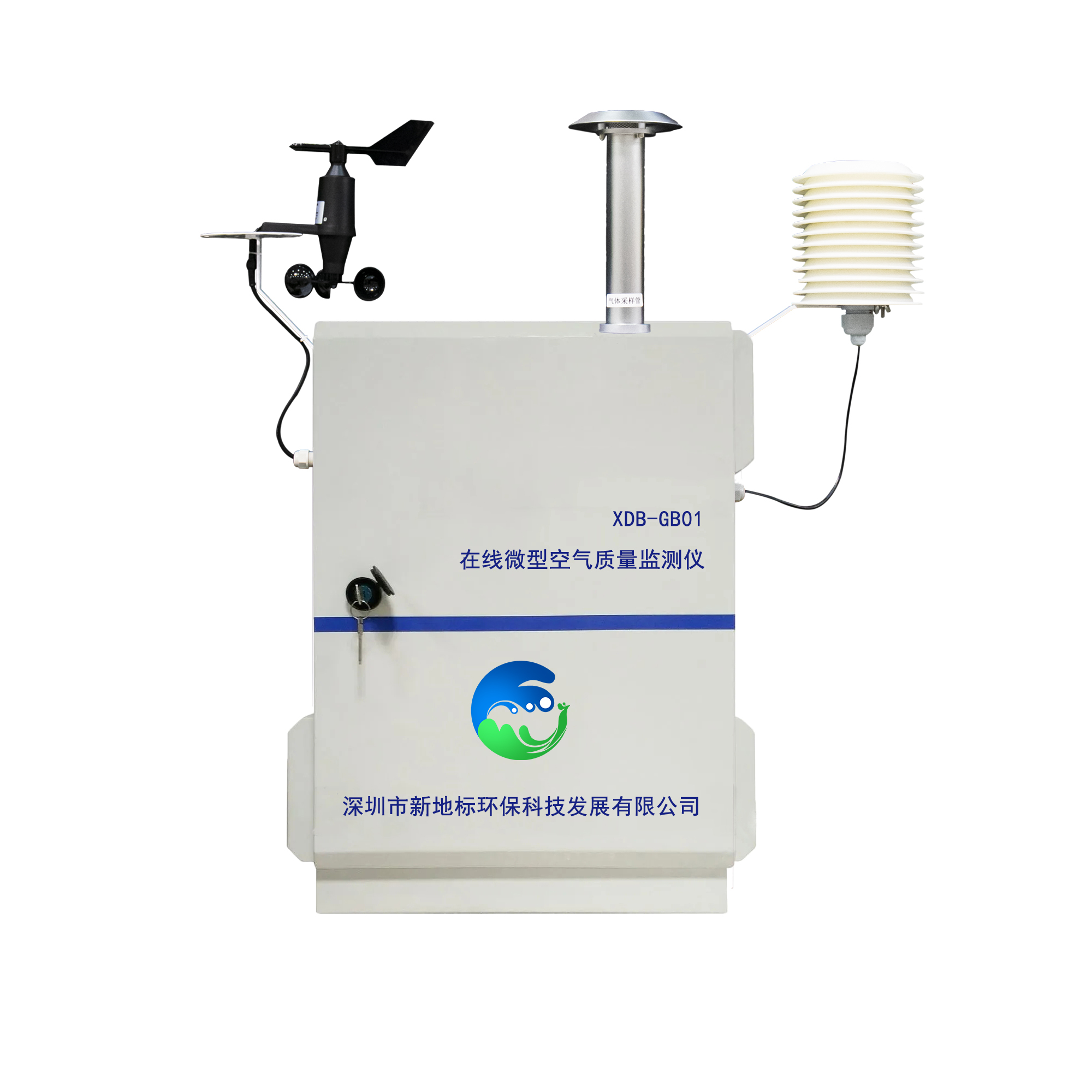

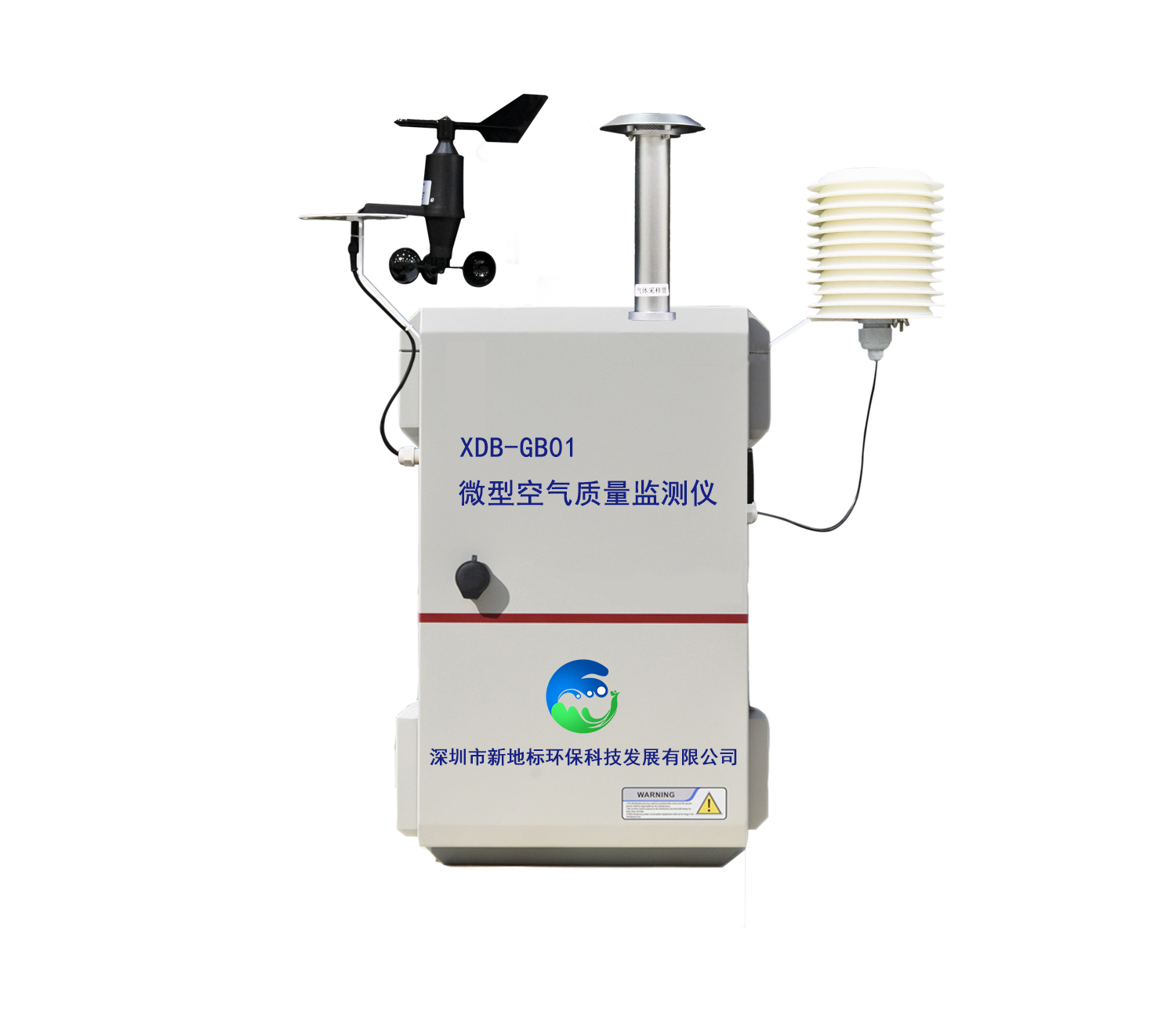

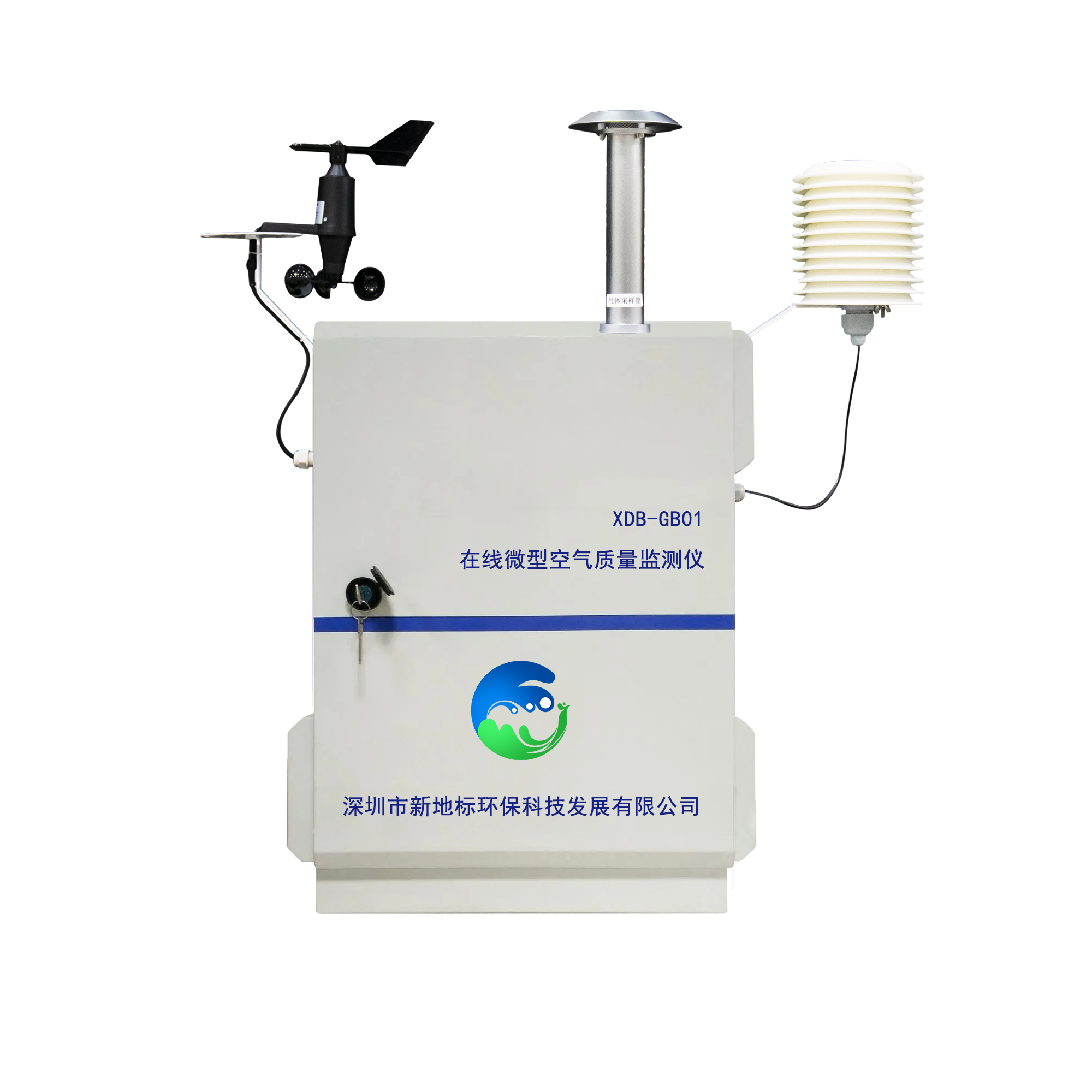

Micro air quality monitor XDB-GB01

First, micro air quality monitor introduction:

This instrument is mainly used for real-time monitoring of ambient air gas, mainly using gas electrochemical sensor, PID (photoionization) detector as the core detection components, is a highly sensitive detector, a wide range of applications, can detect ppb level organic gas, through the built-in air pump to extract ambient air, after sampling pretreatment system processing for concentration detection. Real-time detection of data transmission through the built-in wireless transmission unit. In addition to meeting the current gas concentration monitoring requirements, the system can also monitor meteorological parameters, and reserve a variety of toxic gas sensor expansion and plant unified scheduling, early warning and forecasting functions, which can realize a complete monitoring, monitoring and early warning system of the plant, and promote the harmful gas monitoring business and emergency response level of the plant with information technology. Comprehensively improve production safety and emergency handling capacity.

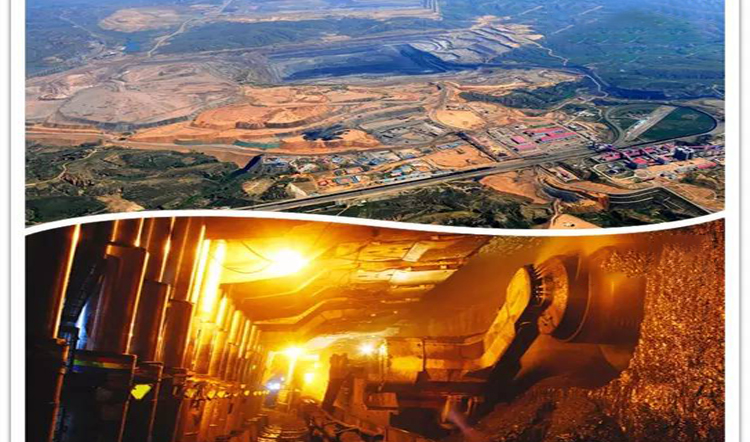

Second, micro air quality monitor uses:

For unorganized emission detection; Unorganized emission means that the exhaust gas generated in the production process is discharged directly to the outside, and it is not discharged through the exhaust cylinder. The sampling location is the main production workshop. The sampling point is set in the workplace near the equipment with high dispersion concentration, and the workplace with the longest exposure time of the worker is considered.

Third, the principle of the detector:

(1) The use of advanced photoionization sensor (PID), which uses an ultraviolet lamp (UV) as a light source to ionize organic molecules into positive and negative ions that can be detected by the detector (ionization), so as to detect the gas concentration. PID sensor is used as the main detector in this instrument. Its principle is shown in the following figure:

(2) The electrochemical sensor works by chemically reacting with the measured gas and generating an electrical signal that is proportional to the concentration of the gas. This device uses the original imported sensor from CITY Electronics, a first-tier sensor brand of Honeywell.

Four, micro air quality monitor features:

1, the gas sampling and processing device, the gas is filtered by water and dust. The instrument adopts a three-layer installation structure, and the detection unit is placed in the middle of the instrument; And through the shell and internal temperature controller to control the temperature of the control equipment at about 40℃, to ensure the accuracy of the sensor in the gas detection;

2, the stainless steel shell is more suitable for the use of VOC detection instruments in chemical parks, effectively preventing the corrosion of corrosive gases and rainfall on the shell, and ensuring the service life of the equipment;

3, built-in imported diaphragm air pump, life up to 10,000 hours, can ensure stable airflow, so that the test results are more accurate;

4, power supply: AC220V mains; Equipped with 12V12AH battery, which can ensure normal operation for 24 hours after power failure;

5, the intake air pretreatment system can handle the humidity and dust in the gas, so that clean gas enters the detector, extending the life of the sensor and ensuring the accuracy of the equipment;

6, perfect function: a single characteristic pollutant monitoring station can realize the monitoring of conventional harmful gases in the ambient air, mainly including SO2, NO2, CO, O3, H2S, NH3, VOCs concentration, accuracy reaches ppb level, dust PM10, PM2.5 monitoring and meteorological part: temperature, humidity, atmospheric pressure, wind speed, wind direction;

7, high precision: gas part detection accuracy reaches ppb level;

8, support automatic correction of zero drift and temperature and humidity compensation;

9, real-time transmission: built-in data transmission terminal DTU, through GPRS and other networks with big data platform docking, support HJ 212 protocol, to achieve real-time upload of user terminal data;

10, easy operation and maintenance: the terminal structure design is reasonable, high reliability, easy installation and maintenance;

11, built-in 8000 hours of imported diaphragm air pump and automatic control of its flow at 1.0L/Min;

12, external air pretreatment device, can effectively filter dust and water vapor;

13, the shell has a temperature self-regulation function, equipped with heat shield and through the nano heat insulation spray material and internal circulation system to effectively control the temperature of the box.

4. Sensor parameters:

monitor

Parameter Working principle Detection range resolution Sampling flow accuracy

SO2 Electrochemistry 0 ~ 2ppm 1ppb 1L/min ± 5%FS

NO2 Electrochemistry 0 ~ 2ppm 1ppb 1L/min ± 5%FS

CO Electrochemistry 0 ~ 50ppm 50ppb 1L/min ± 5%FS

O3 Electrochemistry 0 ~ 2ppm 1ppb 1L/min ± 5%FS

H2S Electrochemistry 0 ~ 30ppm 0.1ppm 1L/min ± 5%FS

NH3 Electrochemistry 0 ~ 50ppm 0.1ppm 1L/min ± 5%FS

VOCs PID 0 ~ 50ppm 10ppb 1L/min ± 5%FS

TSP laser scattering method 0-10 mg/m³ 0.001 mg/m³ 2L/min ± 5%FS

PM10 laser scattering method 0-1-10mg/m³ 0.001 mg/m³ 2L/min ± 5%FS

PM2.5 laser scattering method 0-1-10mg/m³ 0.001 mg/m³ 2L/min ± 5%FS

Meteorological parameters:

Temperature measuring range -50 ~ 80° C; Accuracy ± 0.2

Relative humidity measurement range 0 ~ 100% relative humidity; Accuracy ± 2%

Pressure measurement range 10 ~ 1300 hpa; Accuracy ± hpa

Wind direction mechanical, measuring range 0 ~ 360° , 16 orientation, resolution ± 22.5 & deg;

Wind speed mechanical, measuring range 0 ~ 30 m/s

Starting wind speed: ≥ 0.5 m/s, resolution 0.1 m/s

Noise parameters:

Noise measurement range 35-120db

Accuracy ± 5db

5. Equipment parameters:

Detection principle Photoionization, electrochemistry, laser scattering

Sampling mode Pumping type

Working power supply AC220V, solar energy

Output mode wired (RS485), wireless GPRS (reliable transmission using TCP)

Detection accuracy ± 5%FS

Response time <15s

Installation mode Wall hanging or riser installation

Service life Host: 5 years

PID sensor: (body 2 years, UV lamp 6 months replacement)

Electrochemical sensors: 1 year

Operating temperature -30℃~50℃

Operating humidity 0~95%RH (no condensation)

简体中文

简体中文 ENGLISH

ENGLISH