XDB-WQ04 Marine exhaust monitoring system

1 System Overview

XDB-WQ04 Marine exhaust monitoring system, the core detection device is mainly infrared gas sensor, electrochemical gas sensor, gas through the pretreatment system, gas acquisition system, sensor signal processing and acquisition system, data processing and storage system, signal transmission system, power control and conversion system. The instrument is used for fixed source detection to determine the concentration of pollutants in as short a time as possible, providing scientific decision-making basis for timely and correct treatment, disposal of pollution accidents and formulation of recovery measures.

1.1 Introduction to the design scheme

Marine exhaust monitoring system is used to detect the concentration of SO2, NO2, CO2, NO gas, applied to environmental pollution accidents caused by sudden factors, for timely and correct treatment, disposal of pollution accidents and the development of recovery measures to provide scientific decision-making basis.

Considering the function to be realized and the volume of the instrument, power consumption and other factors, the detector adopts an integrated design to integrate the required components to the greatest extent.

Marine exhaust monitoring system is mainly composed of power supply module, gas circuit system, main control system, exhaust sensing module group, communication module and storage part.

1.2 Working principle of gas detection sensor

Detection principle:

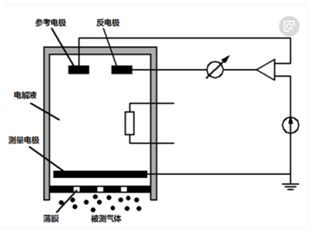

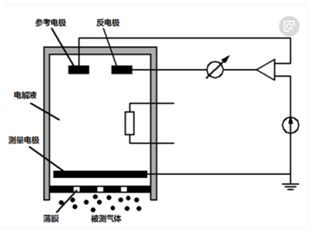

1, gas electrochemical sensor detection principle

The electrochemical sensor works by chemically reacting with the measured gas and generating an electrical signal proportional to the concentration of the gas, the principle of which is shown in the following figure:

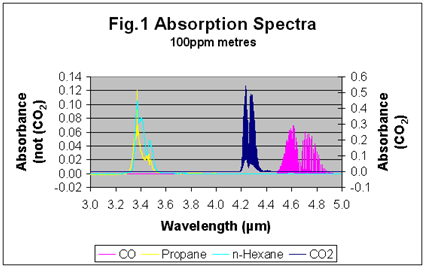

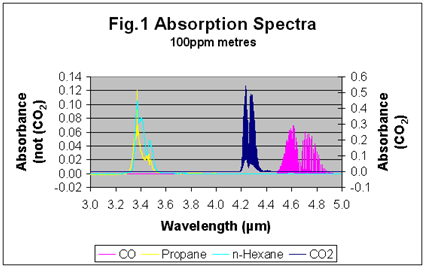

Table: Absorption spectrum

Technical parameters of ship exhaust gas monitoring system

1. System composition

※1, main monitoring indicators: sulfur dioxide (principle for constant potential electrolysis), nitrogen dioxide (principle for constant potential electrolysis), nitric oxide (principle for constant potential electrolysis), carbon dioxide (principle for non-dispersive infrared).

* 2, other indicators: temperature (principle of resistance or thermocouple), relative humidity (principle of resistance or capacitive humidity sensitive method);

3, equipment function: under normal conditions using 4G signal to send the collected data to the server. When there is no 4G signal at sea, the equipment uses LORA for data communication with the receiving end of the patrol boat, and the receiving end forwards the data to the server. GPS is used to locate the working position of the device. Equipped with TF card for data storage.

4, the equipment is integrated design, the detection parameters have strong anti-cross interference ability.

5. Sampling system: composed of sampling head, pretreatment, 1L/min brushless diaphragm air pump, filter, etc.

6, data transmission: good compatibility, built-in standard custom protocol to communicate with the server or shipborne wireless communication equipment.

Second, performance characteristics

* 1, integrated design can simultaneously monitor sulfur dioxide, nitrogen dioxide, nitric oxide, carbon dioxide, temperature, humidity;

2, built-in 4G, LORA module, can achieve real-time monitoring data transmission;

※3, built-in brushless air pump and can control the gas flow through PWM;

※4, the use of imported high-sensitivity sensor, fast response, high resolution, good linearity, the detection limit needs to meet the requirements of technical indicators;

※5, provide dual interface of main power and backup power; It can automatically switch to ensure that the sensor is in the ready monitoring working state in real time;

6, the application of single-chip microcomputer technology and network communication technology combined, built-in TF data card storage function, data storage requirements for.CSV file; The data can be transferred to the computer through the USB interface, and the data can be viewed using excel and other software;

7, the system requires stable performance, high accuracy, easy operation, easy maintenance, with working status reminders and other functions.

3. Instrument performance index

Indicators: (1) Monitoring indicators: sulfur dioxide, nitrogen dioxide, nitric oxide, carbon dioxide, temperature, humidity.

No. Indicator Name Monitoring Technique Main technical parameters must be met

1 Sulfur dioxide pump suction, electrochemical measurement range: 0-2PPM; Accuracy: ± 5% FS

2 Nitrogen dioxide pump suction, electrochemical measurement range: 0-2PPM; Accuracy: ± 5% FS

3 Nitric oxide pump suction, electrochemical measurement range: 0-2PPM; Accuracy: ± 5% FS

4 Carbon dioxide pump suction, NDIR method measurement range: 0-5000 PPM; Accuracy: ± 3%FS adopts dual-channel detection and requires a reference optical path

5 Temperature resistance or thermocouple method range: 0-50℃

Accuracy requirements: ± 0.5 ℃

6 Humidity resistance or capacitance method range: 0-100%

Accuracy requirements: ± 5%

Other parameter index values

Sampling method (air pump pumping)

Sampling flow 1 L/min

Power supply 8 to 26V/DC

Peak power < 10W

Data output mode 4G, LORA, RS232

Positioning GPS

Data storage SD card

The sampling interval is 1 second

简体中文

简体中文 ENGLISH

ENGLISH