Miniaturized non-methane total hydrocarbon analyzer

XDB-VOC06 miniaturized non-methane total hydrocarbon analyzer, using the latest PID photoionization technology, can monitor ambient air pollutants VOCs, meteorological 5 parameters.

1. Reference standards

HJ 654-2013, Technical requirements and detection methods of continuous automatic monitoring system for gaseous pollutants in ambient air (SO2, NO2, CO, O3);

HJ/T 212-2017 Data transmission standard for Pollutant Online Monitoring (monitoring) system;

HJ/T 524-2009 Air pollutant Name code;

HJ663-2012 Ambient Air Quality Index (AQI) technical provisions (trial);

GB/T 19582-2008 Industrial automation network specification based on Modbus protocol;

GB 50348-2004 "Safety engineering Technical Specification";

GB 50357-94 "Lightning Protection design Code for Buildings";

2. Miniaturized non-methane total hydrocarbon analyzer

The miniaturized non-methane total hydrocarbon analyzer is mainly composed of environmental gas monitoring module, organic volatile matter monitoring module, meteorological monitoring module, display module, data acquisition and wireless transmission unit. Combined with the monitoring platform software, it can achieve air quality release, data comprehensive analysis, pollution alarm and other functions.

Product features:

Modular design, configuration of any combination, easy to set different monitoring factors according to demand, suitable for large-scale grid distribution;

Selection of four-electrode high-precision imported sensor;

The circuit uses an industrial-grade embedded processor, suitable for harsh outdoor environments and operating ambient temperature ranges

(-40~70) ℃;

High precision ADC data acquisition system, able to monitor μ g/m3 level pollutants;

Long life anti-interference sampling power system, quiet, efficient; The sampling period is adjustable;

Use industrial-grade data transmission module, data transmission is stable and reliable; The system adopts dual channel communication mode to ensure data continuity.

It can not only realize remote data transmission, but also read the system status information remotely, and realize remote control, remote modification of instrument parameters, fault diagnosis;

Meteorological parameter test system is optional;

On-site real-time data display: the terminal instrument data update time is adjustable;

Various installation methods, can be selected according to the site situation: bracket installation, hanging rod installation and other ways, any installation method is firm and reliable, can resist the instant 12 wind.

3.1 Principle of the gas module

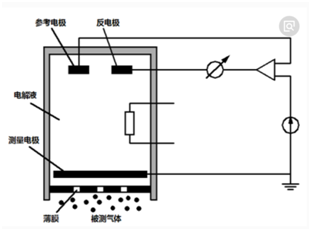

Gas electrochemical sensor detection principle

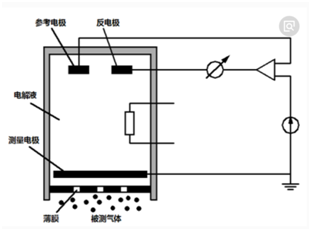

Electrochemical sensors work by chemically reacting with the gas being measured and producing an electrical signal that is proportional to the concentration of the gas. Its principle is shown in the following figure:

Figure: Schematic diagram of electrochemical sensor

The electrochemical gas sensor is a microfuel cell element that requires no maintenance and can have long-term stability. It is improved on the basis of the original oxygen sensor, which can directly reflect the gas concentration without having to reflect the partial pressure.

Electrochemically, the sensor consists of two electrodes. The inductive electrode and the negative electrode, which are separated by an electrolyte film, are sealed by a plastic shell, leaving only a small hole to allow gas to enter the inductive electrode, and the electrode in the sensor is connected to the applied device through the pin. The pin can also be connected to an external resistance circuit, so that the potential difference can be measured when a current passes through. The gas diffused into the sensor is oxidized or reduced on the surface of the induction electrode, and the opposite reverse reaction occurs on the other electrode to form a current on the external circuit. Since the speed of gas entering the sensor is controlled by the gate hole, the current generated is proportional to the gas concentration outside the sensor, and the current gas content can be directly measured.

Its main characteristic design component is the gas diffusion fence, which can limit the airflow into the induction electrode, so that all the target gases can reach the electrode surface and react with it, and has continuous chemical activity, so that the sensor has a long service life and good temperature stability.

For example, the reaction that occurs on the electrode of a carbon monoxide sensor is:

Induction electrode: CO + H2O→ CO2 + 2H+ + 2e-

Inverse electrode: ½ O2 + 2H+ + 2e- → H2O

Total reaction equation: CO + ½ O2 → CO2

Similar reactions occur with all other toxic gases that can be oxidized or reduced.

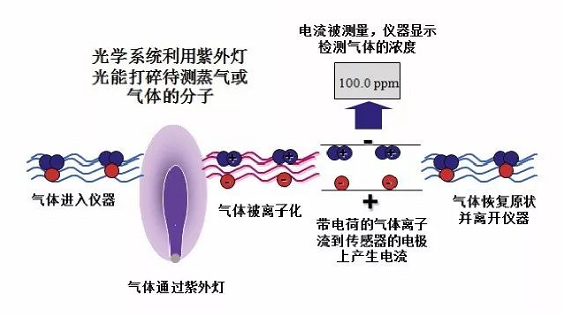

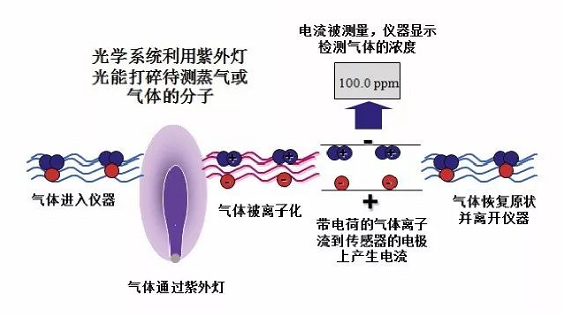

2, VOCs organic gas sensor detection principle

Using an advanced photoionization sensor (PID), it uses an ultraviolet lamp (UV) as a light source to ionize organic molecules into positive and negative ions (ionization) that can be detected by the detector, thus detecting the gas concentration. PID sensor is used as the main detector in this instrument. Its principle is shown in the following figure:

Figure: PID detection principle

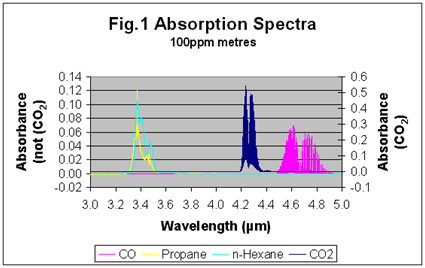

3, gas infrared sensor detection principle

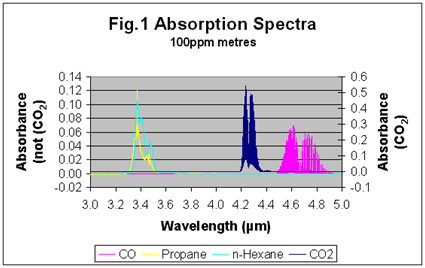

It is well known that 1, many materials can absorb infrared radiation (due to intramolecular vibration). 2, for any kind of material, its absorption capacity changes with the wavelength (its absorption spectrum). 3, different materials have different absorption spectra. The basic principle of the operation of infrared gas sensors is based on the discovery of these facts. Typical infrared spectra are shown in Table 1, including carbon monoxide, propane, hexane, and carbon dioxide.

Figure: Absorption spectrum

3.2 Meteorological monitoring module

Weather monitoring module adopts highly integrated design, can measure the wind speed, wind direction, atmospheric pressure, ambient temperature, relative humidity and other meteorological parameters.

3.2.1 Wind Speed Parameters

Range: 0~30m/s

Response time: 0.25s c. Accuracy: ± 2%

D. Output resolution: 0.1m/s

3.2.2 Wind Direction Parameters

A. Measuring range: 0~360º Accuracy: ± 22.5 & ordm;

Output resolution: 1°

3.2.3 Temperature Parameters

Range: -50~80℃

Accuracy: ± 0.2 ℃

Output resolution: 0.1℃

3.2.4 Relative Humidity Parameters

Range: 0~100% RH

Accuracy: ± 2% RH (0~90% RH)

Output resolution: 1%RH

3.2.5 Atmospheric pressure parameters

Measuring range: 10~1300hPa

Accuracy: ± 1hPa (0~30℃)

± 1hPa (-30~60℃)

Output resolution: 1hPa

3.3 Gas monitoring module

The photoion method is used to realize the monitoring of VOCs, among which the specific specifications of each monitoring module are as follows:

3.3.1VOCs monitoring module

a) Measuring range: 0 ~ 10mg/m3

Resolution: 0.010mg/m3

3.4 Data Communication Module

The data communication module transmits related data through the two-way channel of 4G wireless network, which not only ensures the stability of data transmission, but also reduces the operating cost. Gas concentration, particle concentration parameters, meteorological parameters and other information are transmitted to the data platform through the 4G network, and the 4G wireless network is used to obtain on-site image information and remote control. The system connects to the public 4G network through the Internet of Things wireless data terminal DTU (Data transmission Unit) to provide wireless long-distance data transmission function of IP. DTU system adopts high performance industrial 16/32-bit communication processor and industrial wireless module, takes embedded real-time operating system as software support platform, and adopts WDT watchdog design to ensure system stability. The intelligent data terminal can enter the data transmission state after power-on, and adopts a complete anti-drop mechanism to ensure that the data terminal is always online in the working state.

3.4.1 Data Communication Module Configuration Parameters

Industrial 4G communication module for data transmission, 850MHz/1800MHz dual-frequency, 850MHz transmit power <33dB, 1800MHz transmit power <30dBm, receive power -107dBm

Industrial grade 16/32 bit CPU

Supports the heartbeat mechanism in multiple protocol modes, ensuring real-time online access

Support 1.5V/2V SIM/UIM card, built-in 15kV ESD protection

Power supply range DC5-35V

Operating temperature -30-75º C. Meet more environmental requirements

Can remotely connect to the collection system to view gas, weather and other parameters and equipment working status

简体中文

简体中文 ENGLISH

ENGLISH